Topics

late

AI

Amazon

Image Credits:Natasha Lomas/TechCrunch

Apps

Biotech & Health

Climate

Image Credits:Natasha Lomas/TechCrunch

Cloud Computing

Department of Commerce

Crypto

go-ahead

EVs

Fintech

Fundraising

Gadgets

game

Government & Policy

Hardware

layoff

Media & Entertainment

Meta

Microsoft

privateness

Robotics

Security

societal

distance

startup

TikTok

Transportation

speculation

More from TechCrunch

Events

Startup Battlefield

StrictlyVC

Podcasts

Videos

Partner Content

TechCrunch Brand Studio

Crunchboard

Contact Us

It ’s not every day you come across kombucha playing a starring theatrical role in possible industrial disruption . But here at 4YFN in MWC we got chatting to Laura Freixas about her PhD research undertaking that ’s using a base of the fermented hipster tea to “ upcycle ” organic waste into strand .

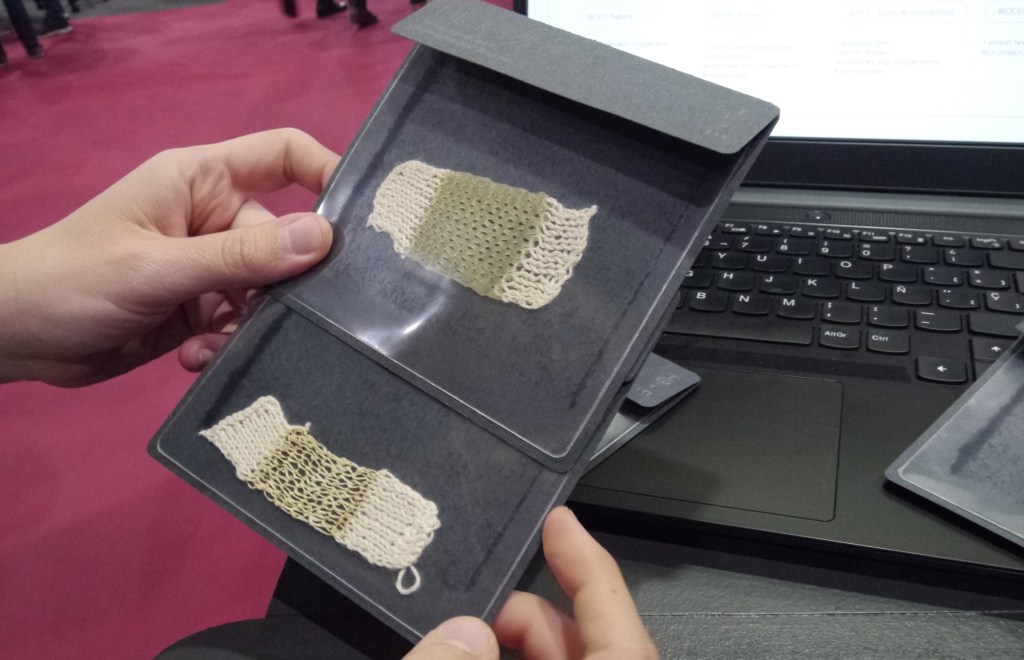

Once action , these biodegradable ribbon can be knitted into fabrics . They can also be treated to have unlike property — such as snap or pee impedance . Freixas had a selection of samples of knitted bio - strand on show , offering a glimpse of eco - well-disposed option to materials like cotton or charge plate fundamentally being brewed into existence .

Freixas is take in charge the project at the Barcelona School of Design and Engineering as part of theElisava Researchteam . They ’re aiming to commercialise the bio - filament — which they ’re calling Biocel . “ The intent is to bio - fabricate filaments from constitutive dissipation because we have catch several problems in the textile industry , ” she state , highlighting the sector ’s many challenge .

While multiple startups have been putting effort into developing eco - well-disposed leathers in recent years , include fungi - based biomaterials from the like ofBolt Threads , MycelandMycoWorks , Freixas says less attention has been paid to devising more environmentally friendly filaments for consumption in fabric yield — despite the textile industry ’s sullen use of chemicals , energy and water ; major problems with pollution and waste ; and an ongoing record of human rights violation linked to wretched workings condition .

Unlike conventional fabric production the methods involved in producing Biocel are not labor intensive and do not require lots of energy or harsh chemical substance , per Freixas . “ This strand is produced with downcast level of caloric energy / electrical energy and no hazardous chemicals , ” she told TechCrunch . “ Then we obtain a biodegradable filum that we can functionalize , or give properties , to be more pliant , stiff or hydrophobic and make a fabric covering . ”

As with making kombucha , the feedstock for producing the bio - filament indigence to have some saccharide for the bacterium to exploit their ferment magic . Which means some farming permissive waste will be better suited — such as grape vine waste ( from wine-colored production ) , or the food grain leave over from brewing beer — owing to relatively high sugar content .

“ Between 15 % and 50 % [ of agricultural products ] become waste when they are processed . Here we see an opportunity , ” she enjoin , pointing to rising regulative demand in the European Union aimed at cut carbon emissions and promoting disk shape that are shifting inducement . It could even lead to a situation in which industrial producers pay upcyclers to take their wasteland off their hands , she suggested .

Join us at TechCrunch Sessions: AI

Exhibit at TechCrunch Sessions: AI

“ Regarding applied science , we are building our machine to automate and monitor the production , ” she said . “ So we are build a digital platform to control the production . And then we also have a patent of invention pending method acting for the tension of the fibril . ”

Future covering for the bio - filum could include weave it into accessories such as shoes and purse for the fashion manufacture ; make biodegradable veiling for product packaging ; or material for furniture , according to Freixas .

Currently she said the bio - filament is not ideal for use of goods and services cases where the crumple material would be in direct contact with people ’s peel , owing to a comparatively raspy grain , but suggested more inquiry could facilitate finesse the finish as they continue to try out with apply different treatments .

“ At this point what we are looking for is for a ship’s company that has a demand — a real need — so we can develop an practical app together and put it in the market so we can formalise and then descale it , ” she added .